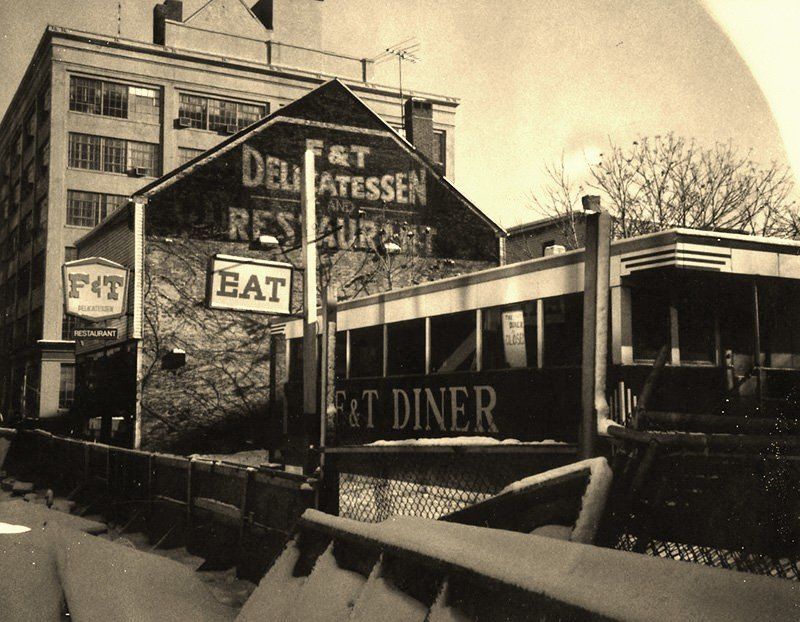

My first job in the food business was at fifteen years old behind the counter at the F&T Diner, an historic fixture in Kendall Square, Cambridge near M.I.T. where I later attended college. At 20, I learned to make ice cream from Gus Rancatore at Cambridge’s world famous Toscanini’s Ice Cream.

After graduation, physics degree in hand I went to work as garde manger at a wonderful restaurant called Michela’s where I was lucky enough to learn basic skills the old fashioned way; boxes of chickens, bags of onions and carrots, and gallons of sauce at a time. Several years (and detours) later, as a bread baker at Stan Frankenthaler’s ‘Salamander’, I took first place Northeast region in the James Beard bread and pastry competition (1995).